Fuel Cell Testing

Fuel Cell Testing: FEV methodologies inside

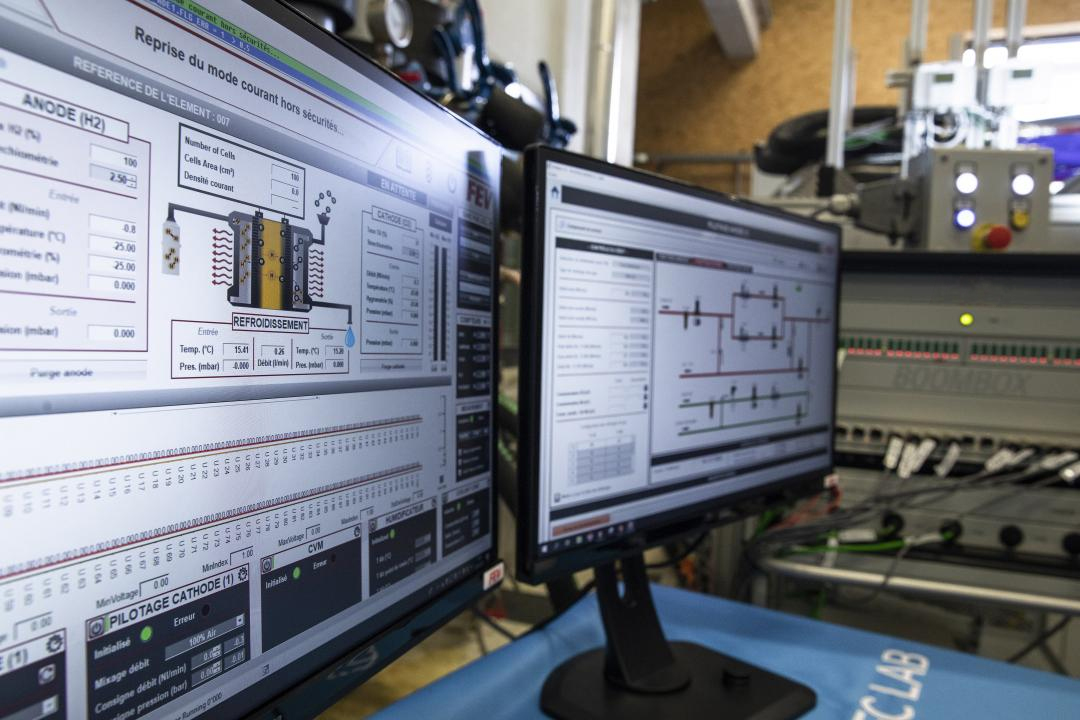

STS helps you to plan, design and set up the right test cell following your individual needs in the field of fuel cell testing. Topics covered include fuel cell testing, stack testing and system tests. Thanks to our universal real-time automation system MORPHEE®, we take care about the overall safety of the test cell as well as the gas infrastructure and the storage of hydrogen in bundles or trailers. We interface the conditioning units filtering the gases and controlling pressure, temperature and humidity of hydrogen. LV and HV components are integrated in order to best analyze the fuel cells at highest quality. From local definition or from a centralized server based FEVFLEX application, MORPHEE® manages all required experiments for fuel cell engine testing, such as startup characteristic tests, rated power tests, peak power tests, dynamic response experiments, steady-state characteristic tests, emergency-stop function tests, insulation tests, system mass tests, reliability durability test and system efficiency tests. With STS, get ready for Hydrogen Fuel Cell testing!

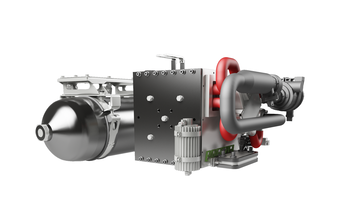

Fuel Cell test bed

Use case

UTBM is an university of technology based at Belfort in France, with a famous laboratory FCLAB devoted to Fuel Cell innovation and Hydrogen Energy.

This test bench was designed and made by STS teams, and funded by region, agglomeration & university.

It is dedicated to evaluate a large range of PEMFC stack (from 10 to 120 kW) :

- Setting up high-power custom fuel cell test bench to support French and European companies for developing hydrogen solutions

- Unique facility in Europe

- Wide operating range for power, gas flow, pressure, temperatures, dew point, with high accuracy & dedicated safety.

- MORPHEE® Automation, Simulation & Acquisition real-time platform: open, scalable & compliant to standard interfaces

- Mobile and modular architecture: easy for users to operate, upgrade & maintain

Download

Discover our other testing solutions.